Best Solvents for Electronics Manufacturing: Isopropyl Alcohol or Acetone?

Share

Best Solvents for Electronics Manufacturing: IPA or Acetone?

A Quick Summary

- Solvents remove oils, flux, adhesives, and dust without damaging components.

- IPA (isopropyl alcohol) is the industry go-to: fast-drying, gentle, and reliable for routine cleaning.

- Acetone is more aggressive for stubborn residues—use selectively and with care.

Introduction

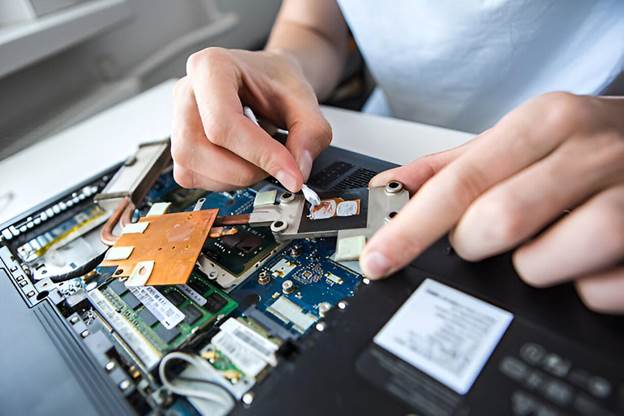

In electronics manufacturing, even tiny contamination—moisture, dust, flux, or fingerprints—can degrade performance and lifespan. The right cleaning solvent prevents defects and rework.

Isopropyl alcohol (IPA) supports a clean, consistent production environment. Acetone shines when IPA isn’t enough. Not every solvent fits every task, so selection matters.

This guide covers the roles, benefits, and limitations of IPA, acetone, and how to use them effectively on electronics.

The Role of Electronics Cleaning Solvents

Contaminants must be fully removed from PCBs and assemblies to avoid corrosion, poor connections, or failures. Solvents are commonly used for:

- Flux and adhesive residue removal

- Removing grease and dust

- Surface prep before coatings or final assembly

- Cleaning static-sensitive components without leaving conductive traces

Choosing the Best Solvents for Electronics

- Evaporation speed: Dry time should match your process cadence.

- Material compatibility: Avoid damage to plastics, coatings, and metals.

- Residue-free: Trace residues can compromise reliability.

For circuit boards and sensitive assemblies, avoid IPA mixtures below 90%.

Isopropyl Alcohol for Electronics Manufacturing

Most manufacturers prefer IPA. It removes oils and light residues without the harshness of stronger solvents. See: Isopropyl Alcohol 99% USP.

Pros

- Fast evaporation

- Clean, residue-free drying

- Compatible with most plastics and metals

- Non-conductive when used correctly

Risks

- Less effective on cured/baked-on flux (may leave performance-impacting residues)

- Flammable—ensure good ventilation and proper storage

Acetone for Electronics Cleaning

Acetone is ideal for precision spot cleaning and removing hardened adhesives, epoxy, and tough grime from small areas without affecting nearby parts.

Pros

- Excellent for stubborn residue and precision cleaning

- Dissolves a wide range of organic contaminants

- Dries quickly and cleanly when used correctly

Cons

- Can attack certain plastics, rubbers, and PCB coatings

- Prolonged exposure can mar surfaces

- Highly flammable—use PPE and ventilate

- Rapid evaporation makes large-area cleaning inefficient

Acetone PCB Cleaning: What You Need To Know

Acetone is effective on stubborn PCB residues—use sparingly and test first. Clean only a small area with a swab/cloth; never immerse the board. Work with ample ventilation.

For community experiences and tips, explore this Reddit thread.

Practical Guidelines for Solvent Use

- Use IPA for routine cleaning: flux removal, contact cleaning, and pre-coating prep.

- Use acetone for epoxy/adhesive removal and heavy contaminants when IPA falls short.

Always follow safety and OSHA guidance.

IPA vs. Acetone: Electronic Component Cleaning

Conclusion

There’s no one-size-fits-all solvent. Match the solvent to the contamination type and material constraints.

- IPA for general cleaning and maintenance.

- Acetone for heavy residues and targeted spot cleaning.

- Use other solvents only when required by specific materials/contaminants.

If you’re unsure what to choose, contact us—we’ll help you select and supply the right option.

The Importance of Bulk Solvent Supply

Maintaining high-grade solvents in bulk prevents costly stockouts and lowers unit cost.

Need steady supply of IPA or acetone? DL Group supplies pure, lab-tested solvents across Canada. Buy manufacturing-ready:

- 70% USP Grade Isopropyl Alcohol

- 99% USP Grade Isopropyl Alcohol

- 99% Tech Grade Isopropyl Alcohol

- 100% Pure Tech Grade Acetone

About DL Group

DL Group offers lab-tested, technical-grade chemicals for industrial applications, including isopropyl alcohol, acetone, hydrogen peroxide, and glycerin. We source and test to ensure purity, safety, and effectiveness.

Safety Tips for Using Electronic Cleaning Solvents

- Work in a well-ventilated space to avoid fume buildup.

- Use an anti-static wrist strap or properly ground yourself before handling sensitive components.

- Wear gloves and safety goggles.

- Store solvents in sealed, labeled containers away from heat, sparks, and sunlight.

- Download our Safety Data Sheets (SDS) for handling and first-aid procedures.

FAQs

Is rubbing alcohol safe for cleaning electronics?

No. Consumer “rubbing alcohol” contains water and additives that can leave residue and cause rust. Use 99% IPA for electronics.

Is acetone safe as a PCB cleaning solvent?

Yes, cautiously. It removes tough residue but may harm plastics/coatings. Test a small area first.

What solvent removes flux best?

IPA works well for most fluxes. For hardened/baked flux, spot-clean with acetone and follow safety practices.

Do IPA and acetone leave residue?

When used correctly, both evaporate cleanly with little to no residue.

Can I clean a circuit board with IPA?

Yes—use 99% IPA, apply carefully, and allow complete drying before power-up.

Is IPA a safe PCB cleaning solvent?

Yes. It’s fast-drying, non-conductive when used correctly, and generally safe for most materials. Ensure ventilation—IPA is flammable.